A new Storm Creek jacket is easily the most complex garment we create. The journey from idea to completed garment is a many-month process. We look at color, fabric, trim and design trends. We source sustainable materials and develop prototypes—all with an underlying focus on quality, fit and sustainability.

We’ll walk you through the journey of two new jackets being designed in our Minnesota-based HQ. We sat down with one of our Senior Designers, Karina Fernandes to hear more about the development process. We hope these insights will help you appreciate the research, thought and expertise that goes into each new jacket.

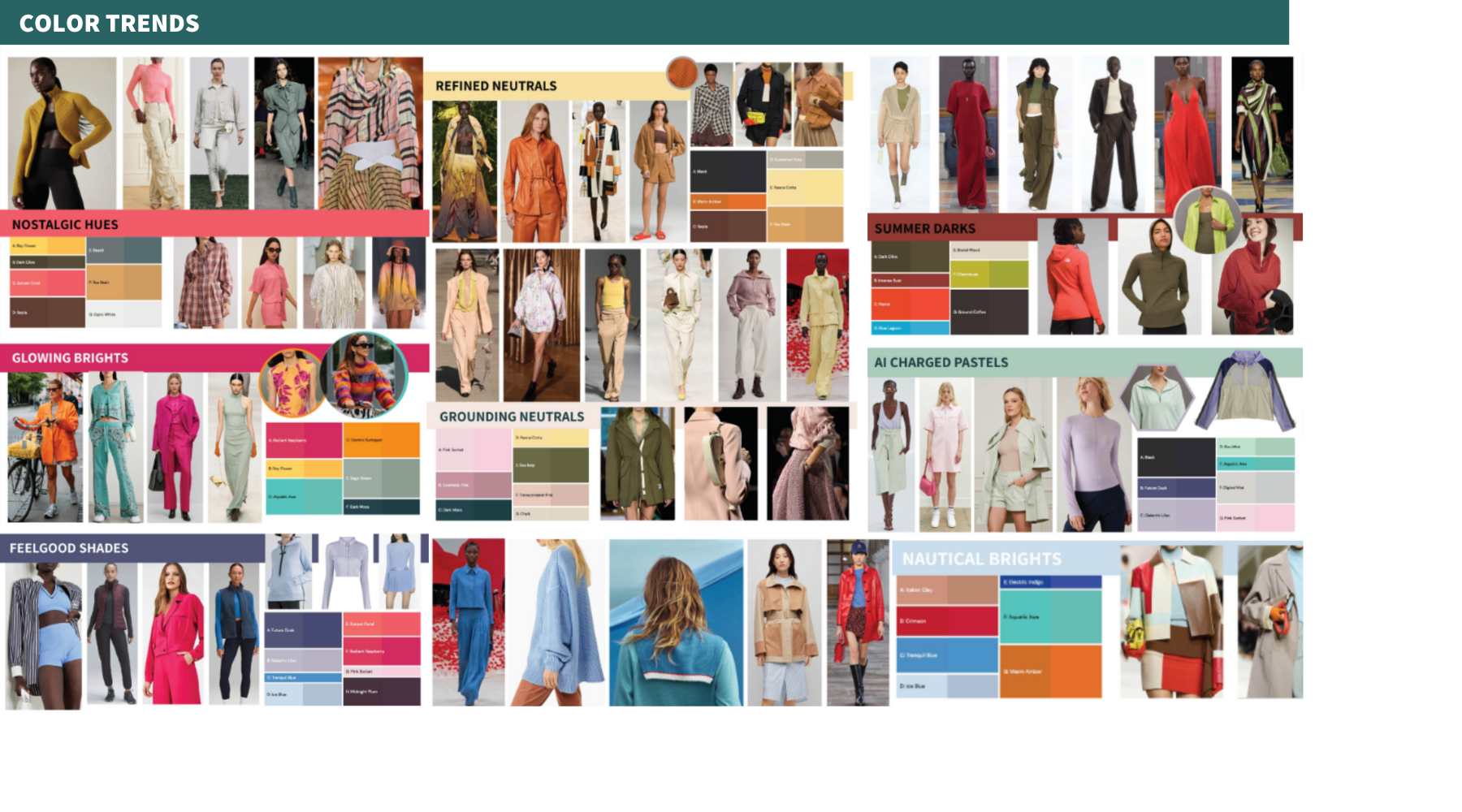

Color Trends and Design Inspiration

Karina and her co-senior designer Jeff Wright start by looking at projected color and design trends for the upcoming season, in this case, Fall 2024/25.

We rely on forecasting services that anticipate future color and design trends across many industries, including fashion. We look at Pantone, Vogue, fashion blogs, Instagram and other online trend-forecasting sources.

The team will research hundreds of websites and pages for ideas of both projected colors and styles. You can see in the images below how they collect their favorites and group them onto boards, keying in on those that are the best fit for us:

These colors and design inspirations are then refined to a very few that are the best fit for Storm Creek’s branding and customers.

For our Fall 24/25 collection, Karina and Jeff chose to pursue a quilted jacket—called the Altitude Jacket—that reflects an updated classic look. They also went with another style that looks much like a modern jean jacket, called the Challenger Jacket. Both styles were supported by their trend research.

Her and Jeff narrow these ideas down and places them on boards as well. These boards reflect specific details—like the quilting patterns.

And the collar style, the length, and fit ideas that translate well as a Storm Creek jacket suitable for both men and women:

Design and Construction

Once the final decision is made for colors and style, the design process begins. Inspired by the boards they put together, Karina and Jeff then focuses on a specific design for each of these two jackets. They go through several rounds of sketches and rough drawings before finalizing the look they’re after.

Eventually, Karina creates the Technical Package for each design. These call-outs go into extensive detail because they’re the instructions the team will send to our factories that create the patterns and prototypes.

Taking the Altitude Jacket as an example, the call-out shows such details as:

- The width of the inside storm flap

- Where the stopper is placed for the bungee cord in the hem

- The size of the zipper used in the inside chest pocket

- The dimensions of the diamond pattern in the quilting

- Even the distance between the two rows of stitching in the quilting and whether they overlap or not

The more detailed and accurate the call-outs are, the more precise and satisfactory the prototype will be.

The length of the design and construction process depends largely on answering two primary questions: First, do we need to source new material? Second, are we creating a new fit? If the answer to these is “yes” the process takes much longer than if it’s an existing fabric or fit.

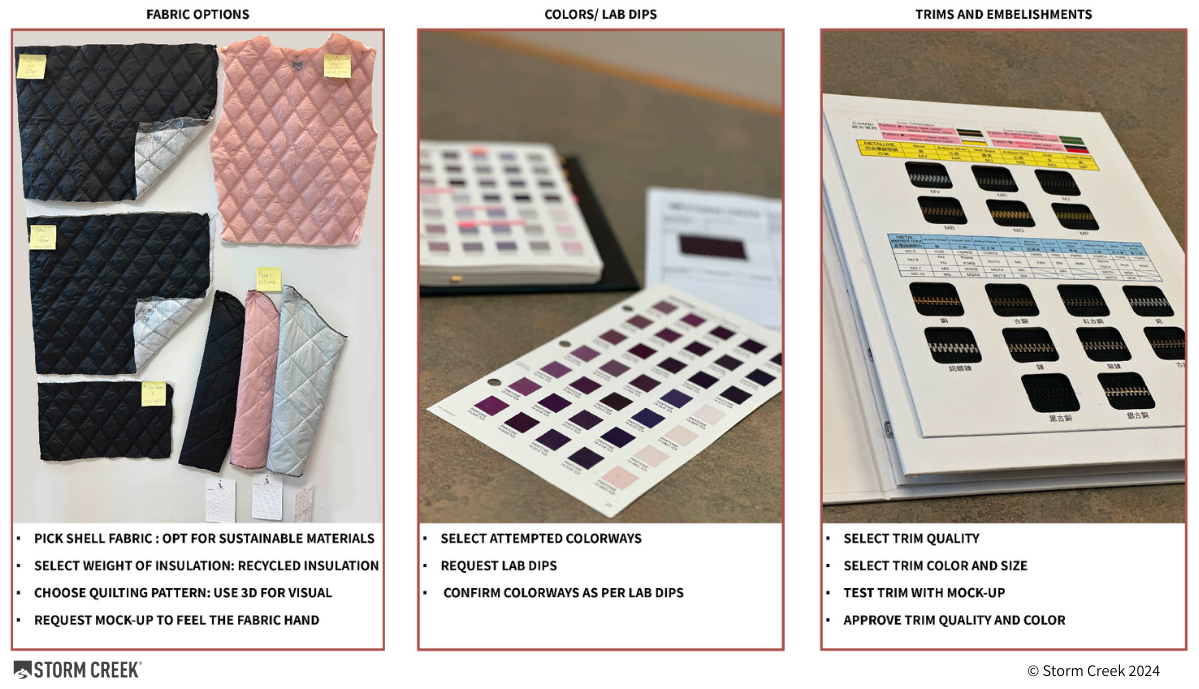

Materials

We have a high standard for the materials we use in our jackets. They need to meet these criteria:

- Is the jacket material comfortable? Soft?

- Are the materials eco-friendly? Not just the fabric but the other elements like thread and insulation?

For jackets in particular we also want material options that will be water and wind-resistant—but that don’t contain harmful chemicals like PFAS.

“Our goal is always to use as many sustainable fabrics, threads and elements as we can in each design,” explains Karina. For the Altitude Jacket, a nylon fabric and recycled insulation was chosen, while they opted for a Blusign-approved recycled nylon for the Challenger.

Once the fabric and colors and chosen, Karin and Jeff request that our partner mills send lab dips—small sample pieces of the fabric in those colors. In this way, they can be sure they like the colors in the chosen fabrics before she commits to hundreds of yards.

When they know they have the correct colors and fabric, Karina and Jeff move on to make decisions for the zippers, snaps, thread and other elements of the jackets. What color zipper will look best? Will there be a drawcord? What kind? What color should it be—contrast or dyed-to-match?

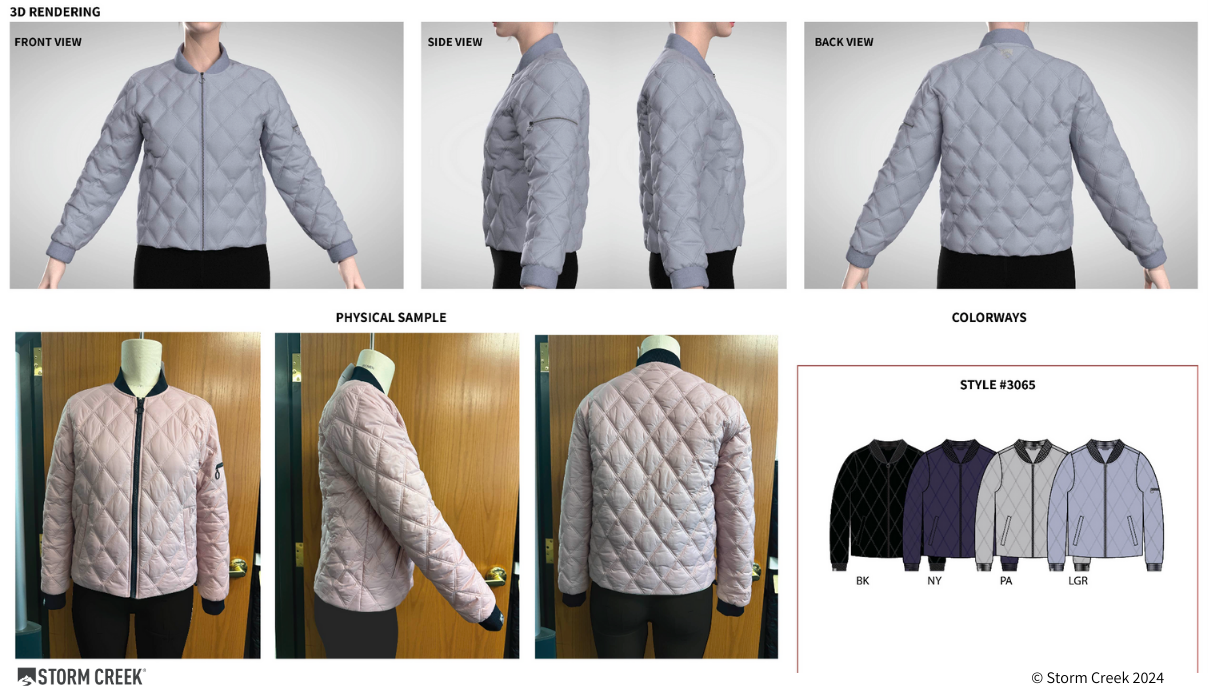

Prototyping Using 3D Rendering

While they wait for a physical sample, Karina likes to have the factory send her a digital sample to examine. Using 3D rendering software called CLO3D, she can examine this digital sample for any design flaws or pattern issues. Having the digital sample allows her to make quick decisions and changes early on, saving valuable time in the whole process.

This board shows images of both 3D rendering and physical samples:

Using Alvanon forms in CLO3D allows Karina to see the full-size set for each design. It helps ensure fit and sizing consistency throughout the product line.

Physical Samples

Our Design Team’s rule of thumb is to go through three prototype models and have their final decision by the third one. The eventual goal is for the first prototype to be rendered as a 3D digital sample, and then have the next two prototypes be physical samples. These physical samples are the final test for fit, functionality and overall design aesthetics.

“When we receive a sample, we measure it and go through a fitting session to be sure the design is approvable and it fits as expected. We communicate any needed changes to the pattern makers and they’ll make the necessary adjustments,” says Karina.

She adds, “Once we’re happy with all the design details and fit expression, the garment is approved. Every measurement and detail must be entered into the Technical Package. That’s how the factory ensures the finished product will look exactly like the approved prototype.”

Adding to Storm Creek's Collection

The entire journey of a new jacket is about 12 months from initial inspiration to having them in stock in our warehouse. It’s always exciting for us to have fresh, new jacket options we can offer our customers.

We’re confident these two models will be a wonderful addition to our current collection!

More to Read: